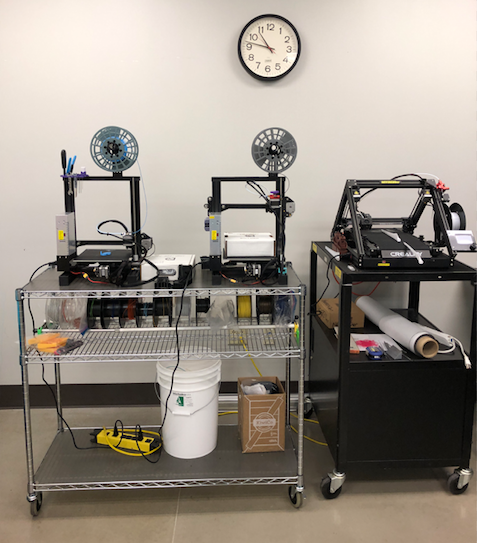

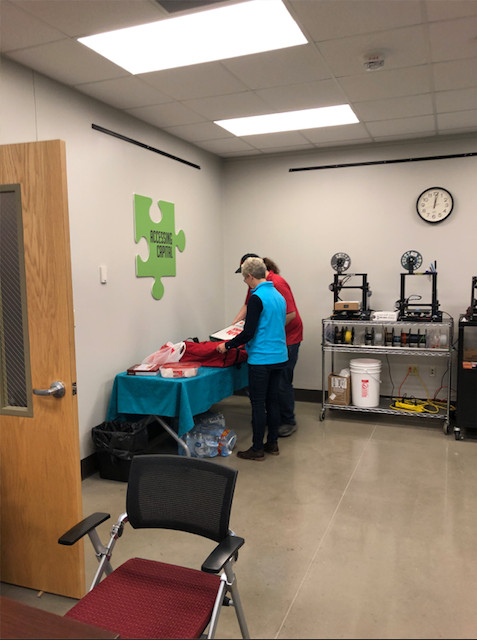

(15) 3D Aficionados: Tom, Bruce, Gil, Charlie, Bernie, Pat, Sam, John H. Bill, Paul, Tom, Ted (Photos), and Mark (virtually via octoeverywhere).

Topic was: “NEVERENDer” a 3D belt printer or PrintMill, along with Filament Types.

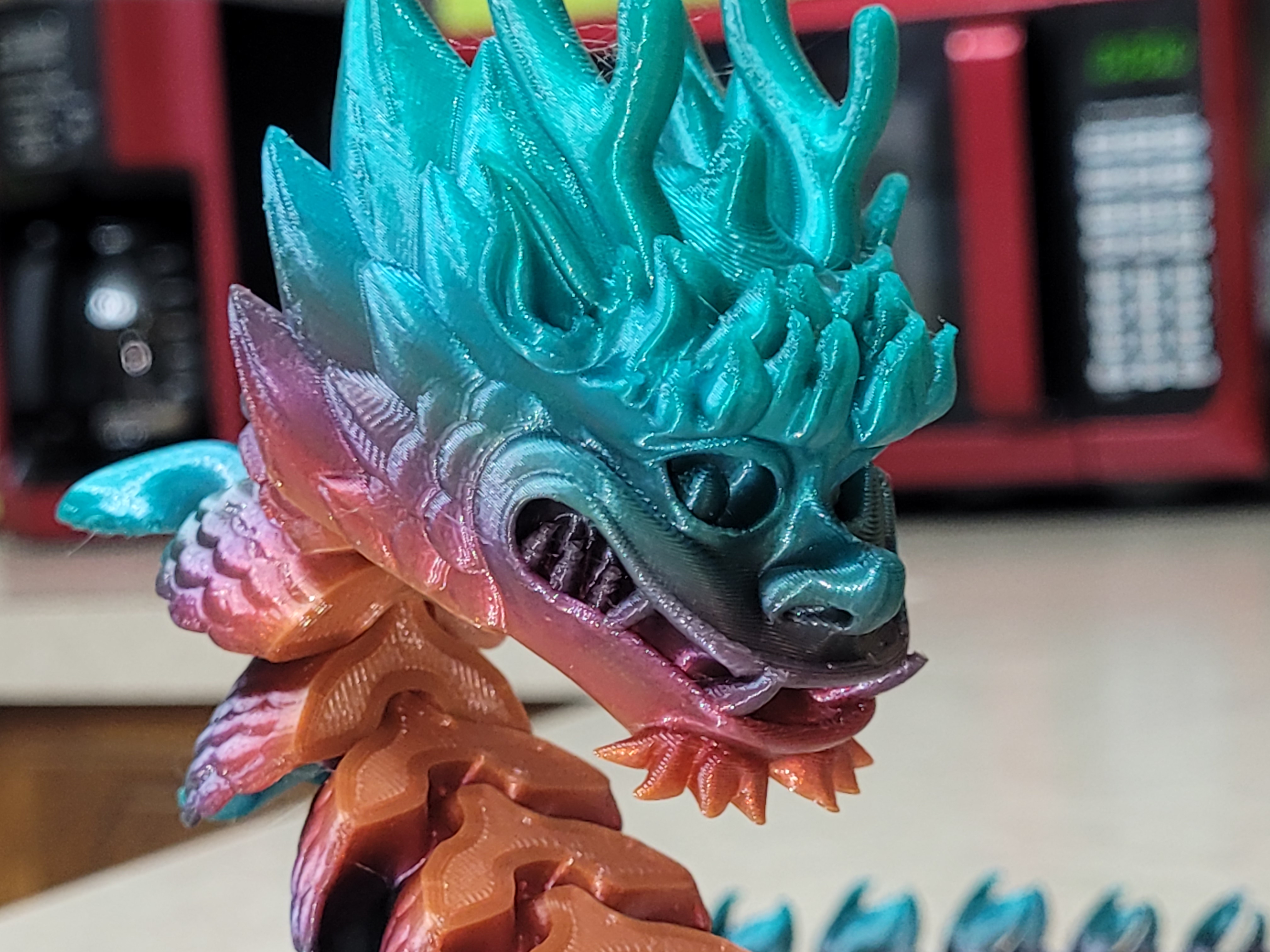

I’m printing these at 230° bed start temp of 75° first layer, 80° 2nd layer, then 85° after layer 21. I’m printing at 45mm/s with a jerk of 20 starting 2nd layer.

Retraction is a 5.5 @ 50mm/s

Infill 0

Walls 3

Bottom initial layers 3

Bottom layer 4

Top layer 5

100% flow except first layer 95%

.2mm layer after initial .28 layer.

Travel is set at 150mm/s but if it wasn’t for all the individual pieces of the Dragon, I get less hair strands at 200mm/s travel but more chance of shaking a part loose.

As far as stringing, I don’t get any due to rapid movement.

My beds don’t have springs either, I have them locked in place.

Running latest version of mriscoc professional firmware, using 9×9 mesh leveling for Dragon and UBL (Unified Bed Leveling) for every print after that. I haven’t adjusted my beds since October and I’ve made a lot of Dragons since then putting out 2 every 19-20hrs.

The Chinese Dragon is a Flexi Dragon that is about 2ft 3in long and it sits up. Can me found on Flexi Factory on Cults 3D.

Pay no attention to the Teflon tubing, I’m running Capricorn in the hotends, but I have 2 heat break tubes I’ll be putting in both printers that are titanium that I can’t Wait for Christmas to be over to test out!

Cheers

Mark Leckington